Quick Change Die

We have designed two systems to quickly and accurately change vinyl cutting tools. This reduces the lost time due to product changes and maintenance. Our Quick Change Dies can be changed in less than one minute!!

OUR DIES

From panels to accessories, our dies are being used to cut many different shapes and profiles of extruded vinyl. Our die shoes are made from QC10 Aircraft grade Aluminum & A36 HRS Steel. We use high quality Hardened Tool Steel for all cutting edges. Our panel dies use a laminated blade to provide a very clean cut improving the quality of the product, and for ease of sharpening. Our Autodetab cutters are designed for ease of adjustment and prevent marking of the panel face. We have a modular design that allows us to use the same components for different size products. Keeping things standard in this non-standard business is our JOB. This also allows us to keep items on the shelf and produce items in mass quantities keeping our replacement costs low and deliveries quick! Our tooling utilizes a Positive Cam design for horizontal cutting (ie, Butt Cutting), versus our competitors cams which uses a spring for retraction, causing Jam-ups.

The Spring slugless dies are ideal for accessory cutting. A dual or quad configuration can be used to cut several pieces at once or to avoid changing dies during a product change. Guillotine dies are ideal for panels such as soffit, which do not require an overlap notch.

Our dies have many features that bring a quick payback to the user. They have been designed to be both durable and light. The ease of adjustment and sharpening helps reduce the cost of maintenance. The use of durable Hardened Tool Steel for cutting edges extends tool life. Other die components are made from anodized aluminum, Bronze, Zinc Plated mild steel or stainless steel to minimize corrosion. Our Dies come complete with a Lubrication Divider valve to provide one shot autolube to all points inside die needing lubricated. A quick change coupling provided, allows a customer to attach the die to the press’s Lubrication system. Or it can be hand lubricated.

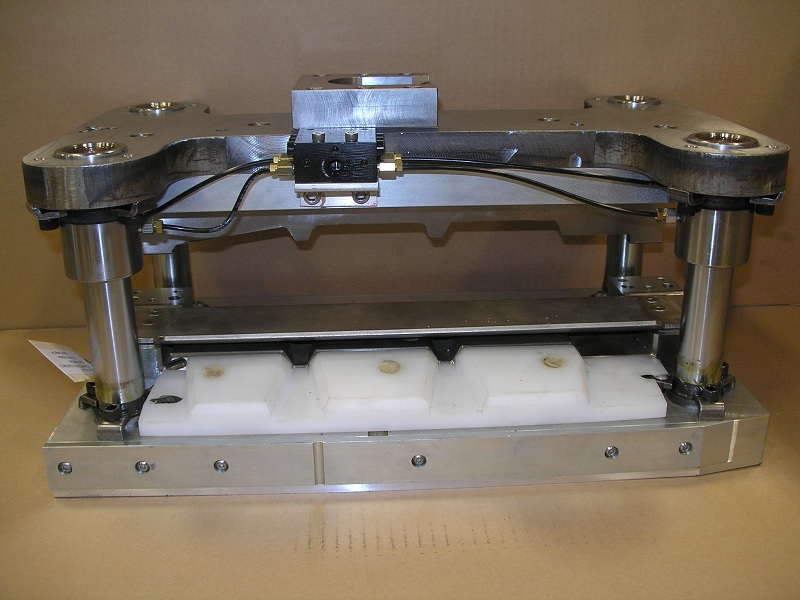

CARRIAGE STYLE QUICK CHANGE

This system starts with carriages that are mounted in the press on the Top & Bottom Press Rails. The dies are easily removed and replaced and are securely held in place with pneumatic clamps. The Lower Bottom Carriage has pneumatic cylinders, rails, wear plates, & an Accelerator Cylinder Bracket that is connected to the accelerator cylinder for flying shear cut off operation. The Bottom Carriage and die can be coupled to the press lubrication system, which lessens maintenance time. The Top Carriage is lubricated by the Bottom Carriage. This system is a standard option for our own line of presses and has been adapted for use in most brands of presses used by the vinyl industry. The dies can also be supplied with rails to be used in end-load applications with minimal assembly back and forth.

RAIL STYLE QUICK CHANGE

This system starts by placing a Rail Mounted Backwards on the opposite operators side of Press top Platen. Then by sliding & attaching Bottom Carriage to Accelerator Cylinder Clevis. With this style, we can keep a standard Press Shut Height between Quick Change & Endload dies. The Dies are easily removed and replaced and are securely held in place by pneumatic Clamps. The Bottom Carriage & Die can be coupled to the press lubrication system. This is a standard option for our own line of High Speed Flying Shear Presses, and has been adapted for use with most brands of presses used in the vinyl industry. The dies can also be supplied with rails to be used in end-load applications with minimal assembly back and forth.

ENDLOAD DIES

We also offer standard Endload Dies for Flying Shear Presses. These dies have a Lower Transition Slide that bolts onto the Bottom Die Shoe. The lower Transition Slide base has rails & wear plates. There are Spacers, Wear Plates, & Rails that bolt onto the Top Die Shoe. This will allow a customer to slide the die into the downstream side of the press for operation.

Remember custom is what we do!

Please contact us with your specific requirements. Our expert die staff awaits the opportunity to meet your needs.

- Published in Design & Build, Vinyl Tooling