All Servo High Speed Flying Shear Press

Similar to our above Mechanical Presses, we offer these presses with a Servo Option instead of a Clutch/Brake for the Crank & Pneumatic Accelerator Cylinder. A Servo Drives the Press Crank & a Servo with a Ball Screw will provide Linear Motion to the Die. These two Servo’s are Electrically Geared together to provide an EXTREMELY ACCURATE CUT! Provided that a consistent signal is being provided from an Encoder. This system will provide Panel lengths consistent to each other in the thousands of inches tolerance realm!

Now s available for order.

This press requires no air, no clutch brake, and will run up to 240 Feet Per Minute!

Remember custom is what we do!

Please contact us with your specific requirements. Our staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Design & Build, Vinyl Tooling

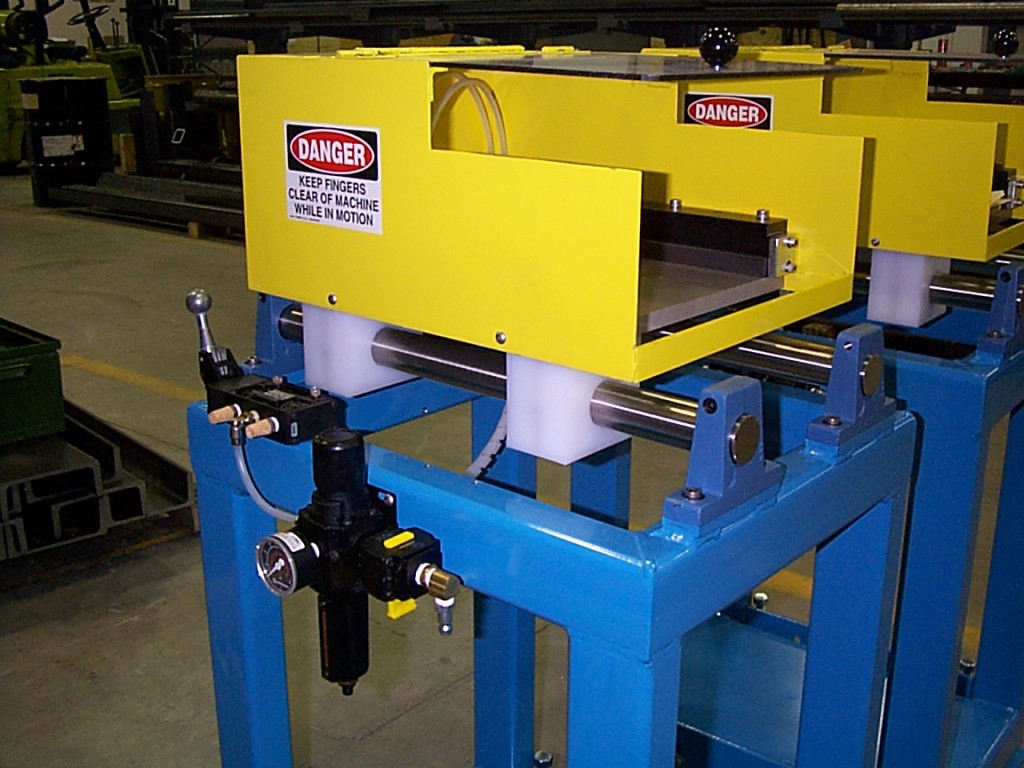

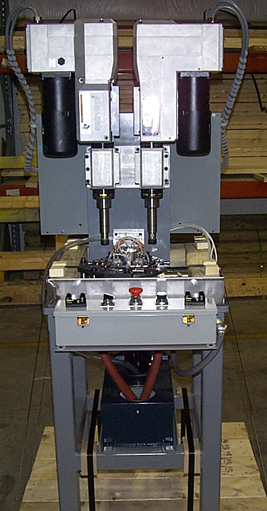

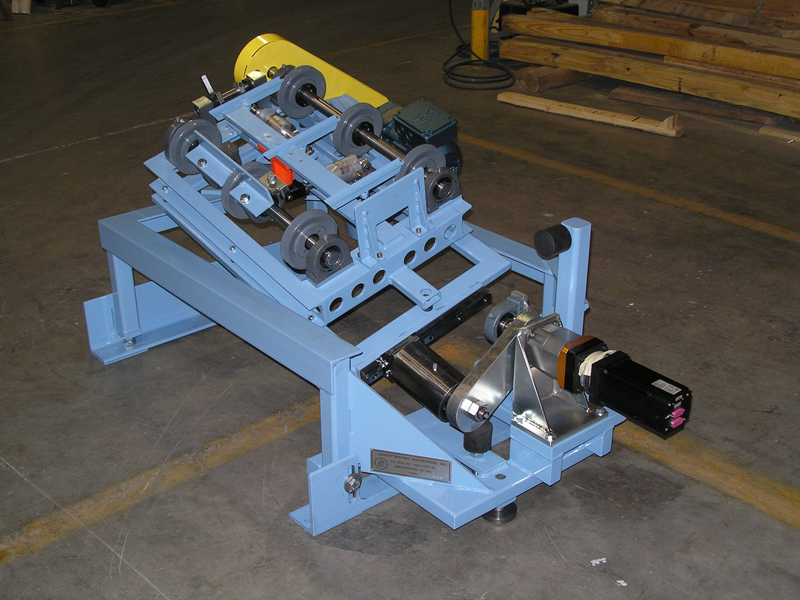

Scrap Cutter

Our scrap cutting machines are designed to contribute to the safety of your operation. Scrap is cut into manageable lengths for regrinding or removal. They eliminate the need for cutting the product with saws or shears and the injuries associated with these methods. Our optional accumulator keeps scrap off of the floor, preventing tripping and slipping hazards. They also reduce the man-hours required during product set-up.

The design of our machine incorporates two knives mounted in rotating shafts. Zero backlash gearing connects the shafts. This causes the material to be cut in a shearing action. The knives are manufactured from Hardened Tool Steel and can be sharpened.

The machine has adjustment to work at most product flight line heights. A speed potentiometer varies the speed of the 5 horsepower DC motor to match the product speed. Speeds up to 240 feet per minute can be accommodated. An adjustable timer is used to vary the length of the scrap to suit the customer’s needs.

We are able to supply a variety of options for this machine. The frame can be supplied with casters to allow either in-line or cross-line movement of the machine. Another frame option is a swing-frame arrangement, which swings the entire machine out of the product line. An optional accumulator table is available to capture the scrap until it can be transferred to a rack or cart. The table has a pneumatic dump action to make this a fast and convenient operation.

The machine is fully guarded and interlocked to guarantee safe operation.

Remember custom is what we do!

Please contact us with your specific requirements. Our engineering staff awaits the opportunity to meet your needs!!

- Published in Custom Machine Building, Design & Build, Vinyl Tooling

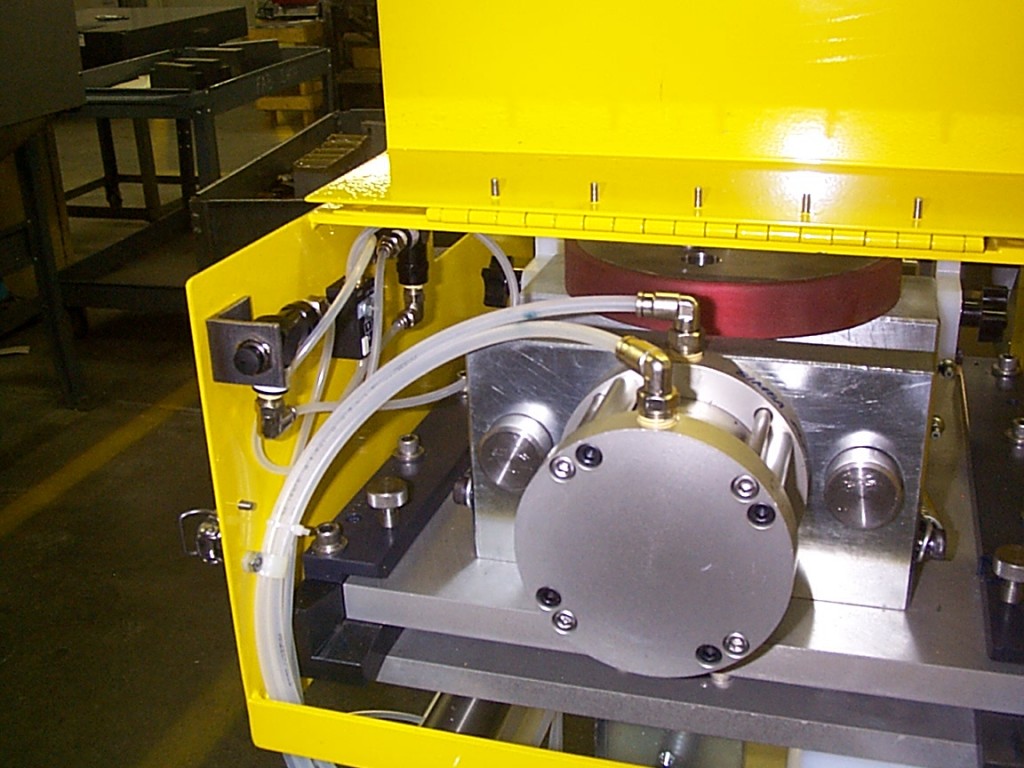

Rotary Weep-Hole

Similar to our Nailslotting line, our Rotary Weep-hole Punch Inserts or Drag style Weep-Hole Punches are being used by a large number of vinyl siding manufacturers at line speeds in excess of 200 feet per minute. They have proven to be effective in producing a quality product while helping to reduce manufacturing costs. Their durability and quality results have made them the choice of many extruded vinyl manufacturers.

The punch wheel is Urethane coated and driven by the product. The punches and anvils are manufactured from high-speed steel and machined to match the customer’s product profile, producing a clean cut. A pneumatic cylinder is used to engage and disengage the punch wheel from the product.

The Weep-hole units are supplied as a quick-change insert. The Weep-Hole Insert can be mounted by itself or on a Puller Mount Quick Change Plate, Stand Alone, or with another piece of equipment, such as a Nailslotter, or Puller. Using our Standard Quick Change Mounts, customers can change a Weep-Hole Insert in less than one minute!

Our Weep-Hole Inserts have many features that bring a quick payback to the user. They have been designed to be both durable and light. The ease of adjustment and sharpening helps reduce the cost of maintenance. The use of durable Hardened Tool Steel & Carbide for cutting edges extends tool life. Other Weep-Hole components are made from anodized aluminum, Bronze, Zinc Plated mild steel or stainless steel to minimize corrosion.

Remember custom is what we do!

Please contact us with your specific requirements. Our expert staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Vinyl Tooling

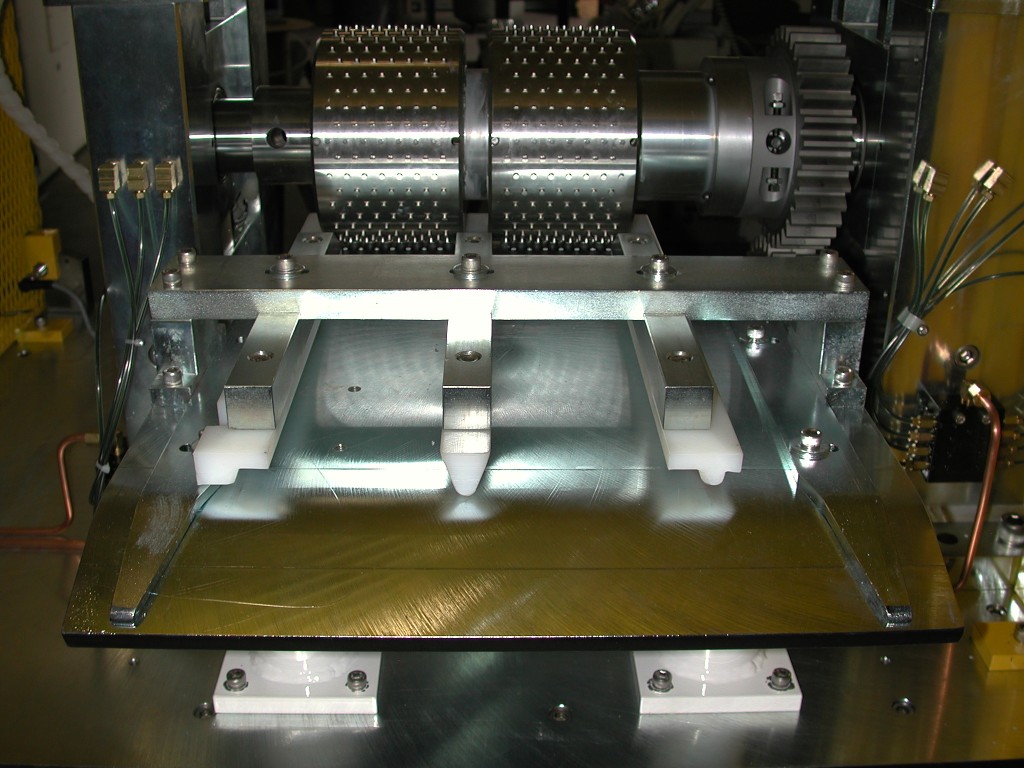

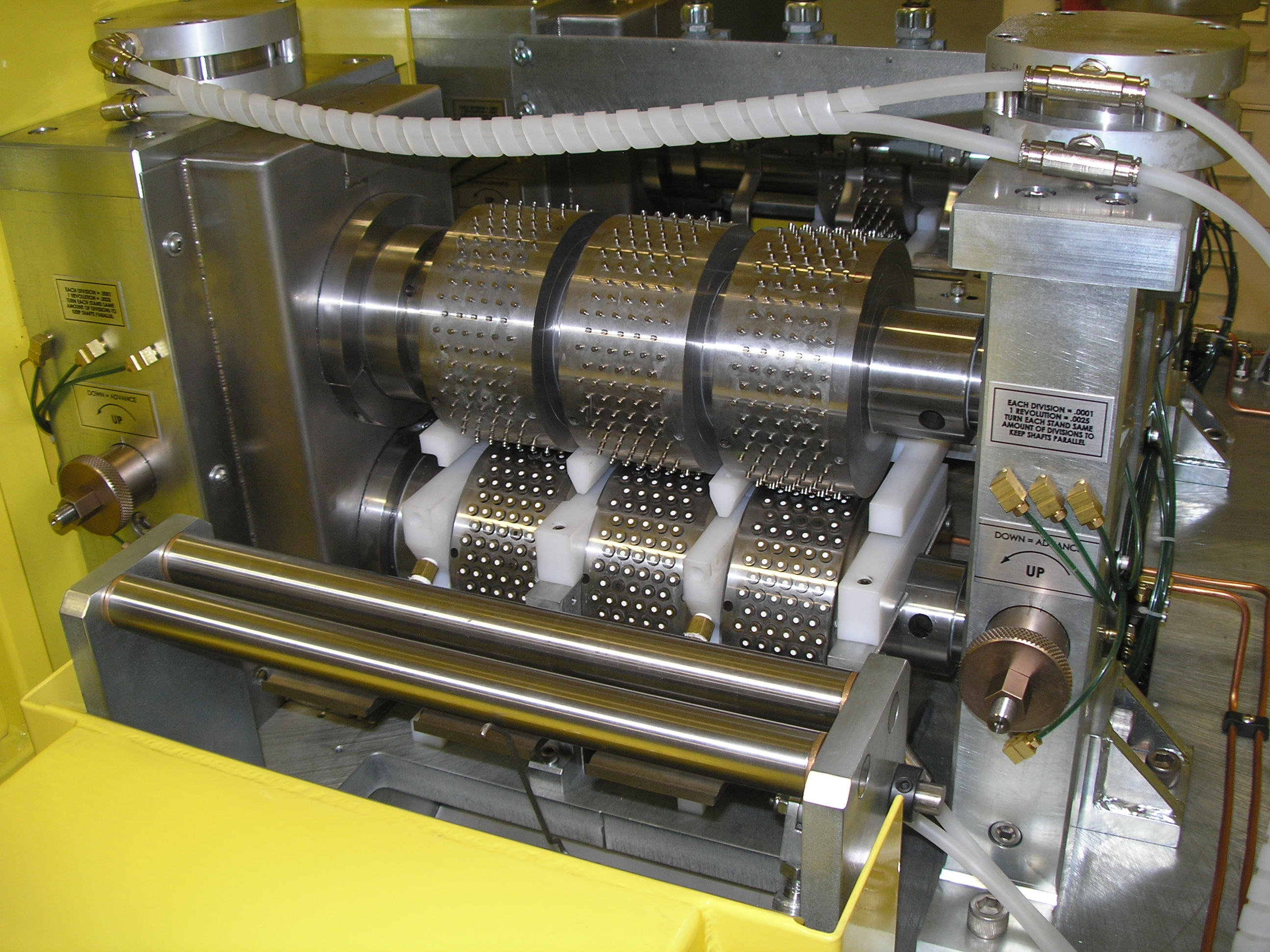

Rotary Perforators

Patterned hole perforators are designed for high speed perforation of vinyl soffit. Hole patterns are the customer’s option. All components are machined to precise tolerances. Precision is critical due to the number of components in this style of rotary perforator. All Punch Rings, Die Button Rings. & Shafts are machined on CNC indexing milling machines that will produce finished part tolerances within +/- 0.0001 inch.

We have designed the Punches and Die Buttons to give exacting production performance. A spring loaded, Precision Ground, Zero Clearance, Antibacklash gear system has been designed to provide precision alignment of the punching and die shafts.

Basket weave perforators are also specially designed for high speed perforation of vinyl soffit. They may be used in the production line or off line as desired by the production crew.

All punching wheels and die wheels are machined to exacting tolerances. This precision punching mechanism will eliminate most of the product distortion normally encountered in this application.

Patterned hole and basket weave perforators can be designed to perforate center vinyl, double five, triple four, or other profiles of soffit with ease, along with Corner Bead (for Plastering applications). Replacement components are reasonably priced and precision made.

Drive motors are AC powered & geared to operate at the customer’s optimum operating speeds. Customer specification of electric drive manufacturer is encouraged to standardize electrical equipment on the production floor. Utilization of a combo PLC\HMI for Speed control & machine functions make operation easy!

Adjustable product guides and fully enclosed safety guards are standard on all rotary perforators.

We can also rebuild existing patterned hole or basket weave perforators and manufacture any needed replacement parts for the worn equipment.

In order to perforate extruded vinyl, an extremely rugged and accurate machine is needed. Alignment of punches to dies is critical to long cutting life and a quality product.

Our perforating machines accomplish this through use of zero backlash gearing. This gearing, along with holding tight tolerances on all parts, produces a machine that will enhance productivity and improve quality.

We also manufacture machines to produce a basket-weave pattern. The absence of slugs makes this a desirable process to some manufacturers.

Remember custom is what we do!

Please contact us with your specific requirements. Our expert staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Design & Build, Videos, Vinyl Tooling

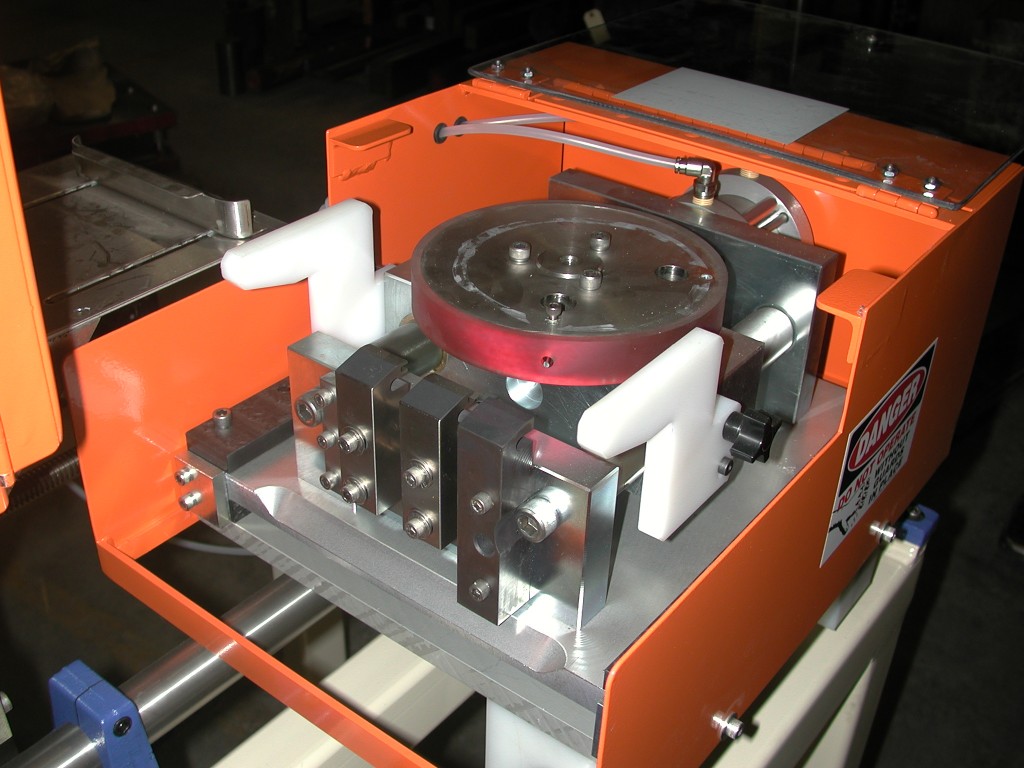

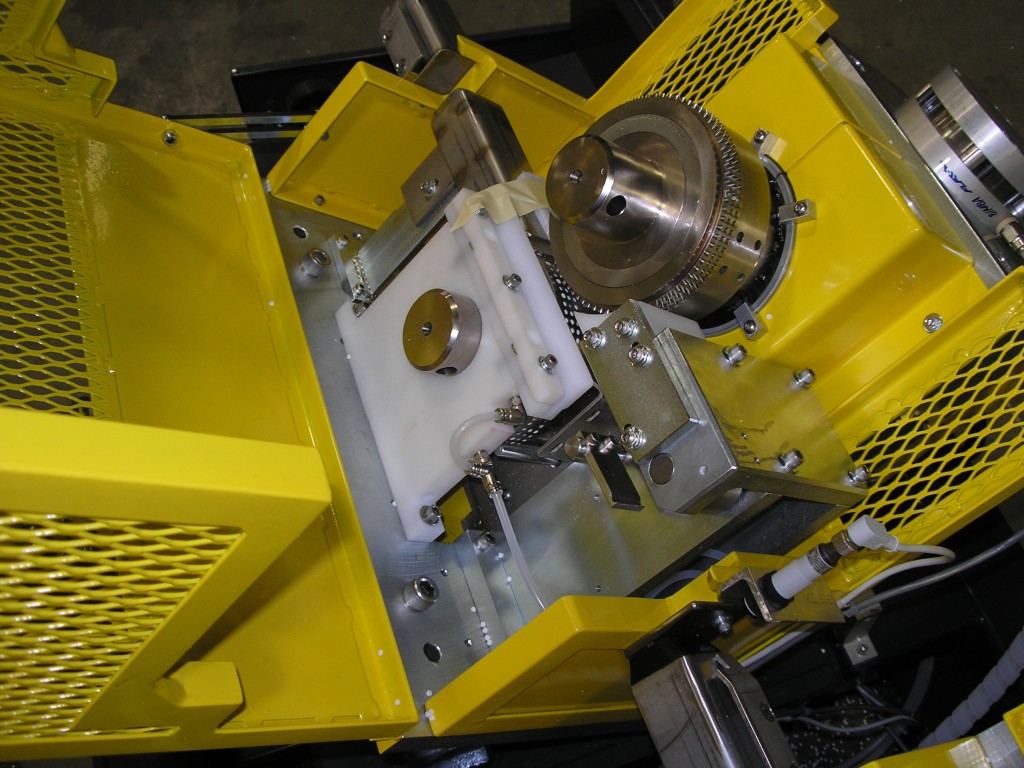

High Speed Flying Shear Press

A press that cuts consistently is a valuable asset to the extruder’s process. It allows for a more consistent panel length, thereby reducing scrap and also allowing the extruder to run their cut length at the bottom of their tolerance, hence saving material.

Our presses are designed to accomplish this goal. The oil shear clutch and brake causes the top platen to stop more consistently than the systems used on other brands of presses. In addition, the control system is constantly adjusting to the variables of air pressure and temperature. Special consideration was given to designing a press that would be safe, durable and require little maintenance.

Our Full Size Press has two different Rail spacings (size suitable to run Skirting panels), while our Midsize Press has only one Rail spacing. All Press Rails are manufactured from Hardened & Precision Ground Tool Steel, to provide Accuracy & long life! Our Top Guard hinges and swings out of the way to provide access from 3 sides. An Automatic Lubrication System lubricates all Press moving parts as well as providing (2) Flexible lubrication lines to attach to the Dies or Carriages.

A complete quick-change die system is available to be used in these presses. With this system, dies can routinely be changed in less than 1 minute.

Please review the specifications to see which one of our presses could be an asset to your manufacturing environment.

- Published in Custom Machine Building, Design & Build, Vinyl Tooling

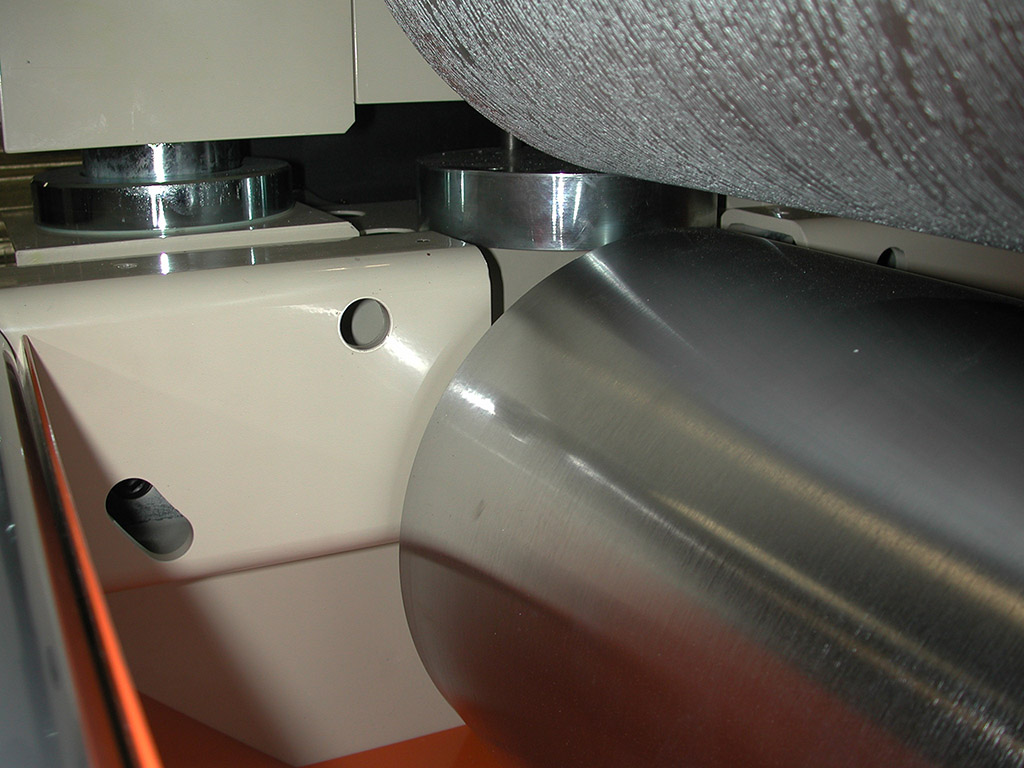

Embossing Roll Stands

The ability to change quickly from one product to another is a big advantage that our embossing roll stand offers. It is rugged and durable yet simple to operate.

The stand can hold between 1 to 4 Embossing Rolls, with 1 lower Rubber Roll. Pneumatic cylinders raise the rolls to allow them to be switched in just a few minutes. The stand also contains either 2, 3, or 4 integral Temperature Controlling Rolls to help cool or heat the material before entering the remainder of the line. The entire stand is mounted on tracks, which allow it to be moved during setup or maintenance. Customer specification of Electric Drive manufacturer is encouraged to standardize electrical equipment on the production floor. The standard unit has two separate Drives, with the Temperature Controlled Rolls being slaved to the Master Drive for the Rubber Roll. Heated Oil is circulated thru the Embossing Roll, while Chilled water is circulated thru a Pan in which the Rubber Roll revolves in. Separate Temperature controlled water is pumped thru the Temperature Controlled Rolls.

Simple Embossing Stands are also available!!

Remember custom is what we do!

Please contact us with your specific requirements. Our expert staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Vinyl Tooling

Electrically Heated Embossing Machines

Our electric embossing stand is ideal for situations where safety or availability prohibits the use of heated oil. A three phase electric supply along with compressed air is all that is needed to make the unit function.

An AC variable speed drive allows the operator to perfectly match the speed of the product. The drive can be interfaced with the process encoder to allow for variance in product speed. Air cylinders engage and disengage the heated roll. A precision thermostat controls the roll temperature to maintain a consistent process by using Heat Cartridges that are inserted into the Embossing Roll.

A wide variety of patterns can be machined into the roll.

Remember custom is what we do!

Please contact us with your specific requirements. Our design staff awaits the opportunity to meet your needs

- Published in Custom Machine Building, Vinyl Tooling

Rotary Indexing Honing Machine

- Published in Automation, Custom Machine Building, Design & Build, Vinyl Tooling

Tilt Table

- Published in Custom Machine Building, Design & Build

Rod and Brush

- Published in Custom Machine Building, Design & Build

- 1

- 2