Rotary Perforators

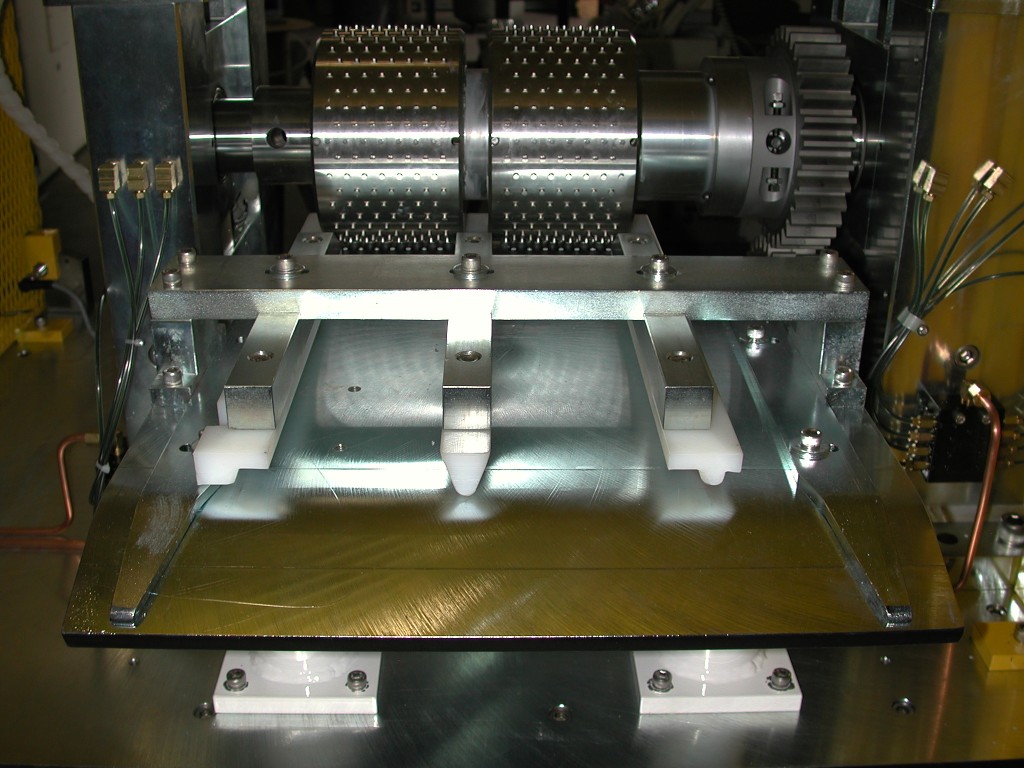

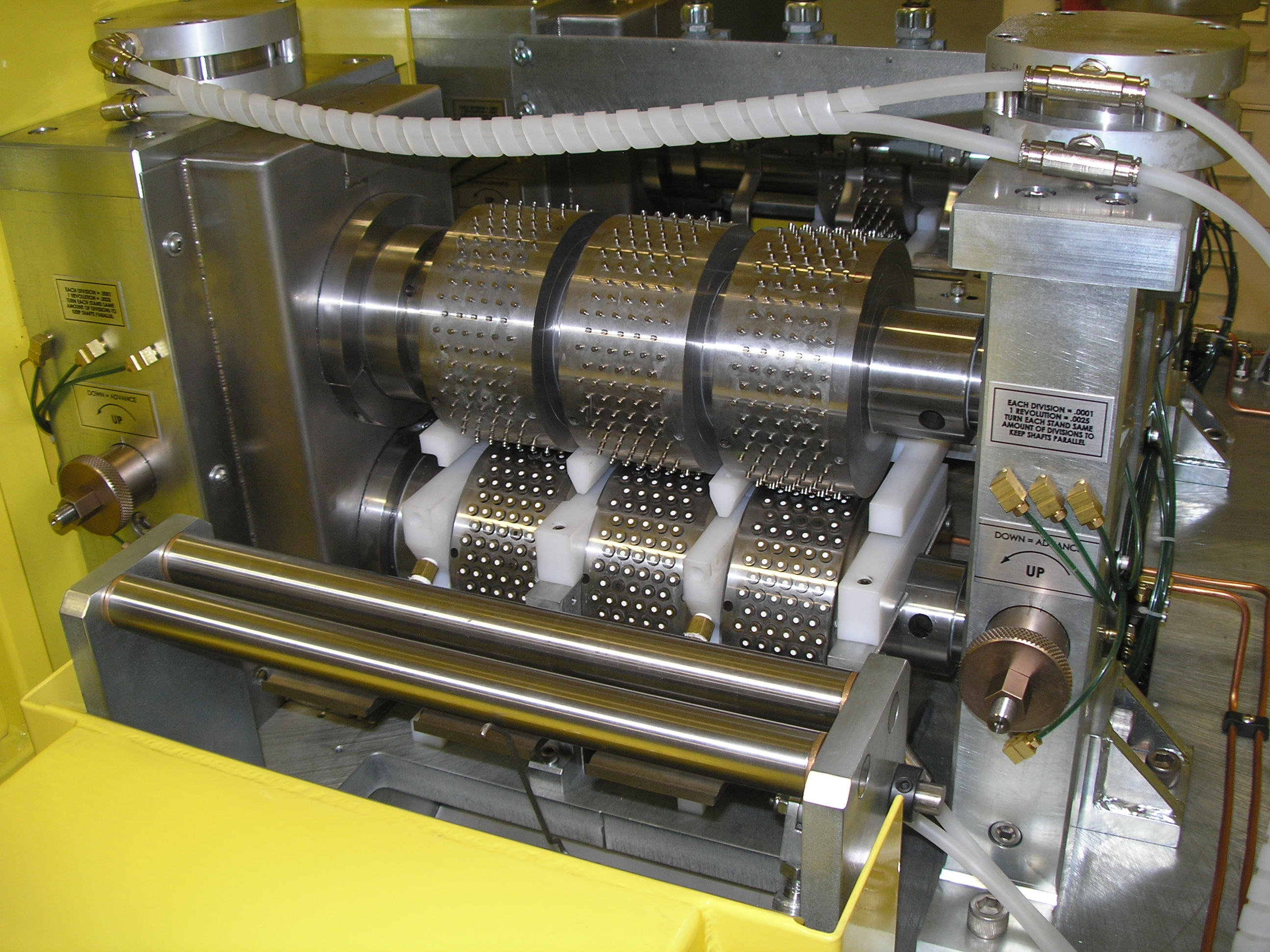

Patterned hole perforators are designed for high speed perforation of vinyl soffit. Hole patterns are the customer’s option. All components are machined to precise tolerances. Precision is critical due to the number of components in this style of rotary perforator. All Punch Rings, Die Button Rings. & Shafts are machined on CNC indexing milling machines that will produce finished part tolerances within +/- 0.0001 inch.

We have designed the Punches and Die Buttons to give exacting production performance. A spring loaded, Precision Ground, Zero Clearance, Antibacklash gear system has been designed to provide precision alignment of the punching and die shafts.

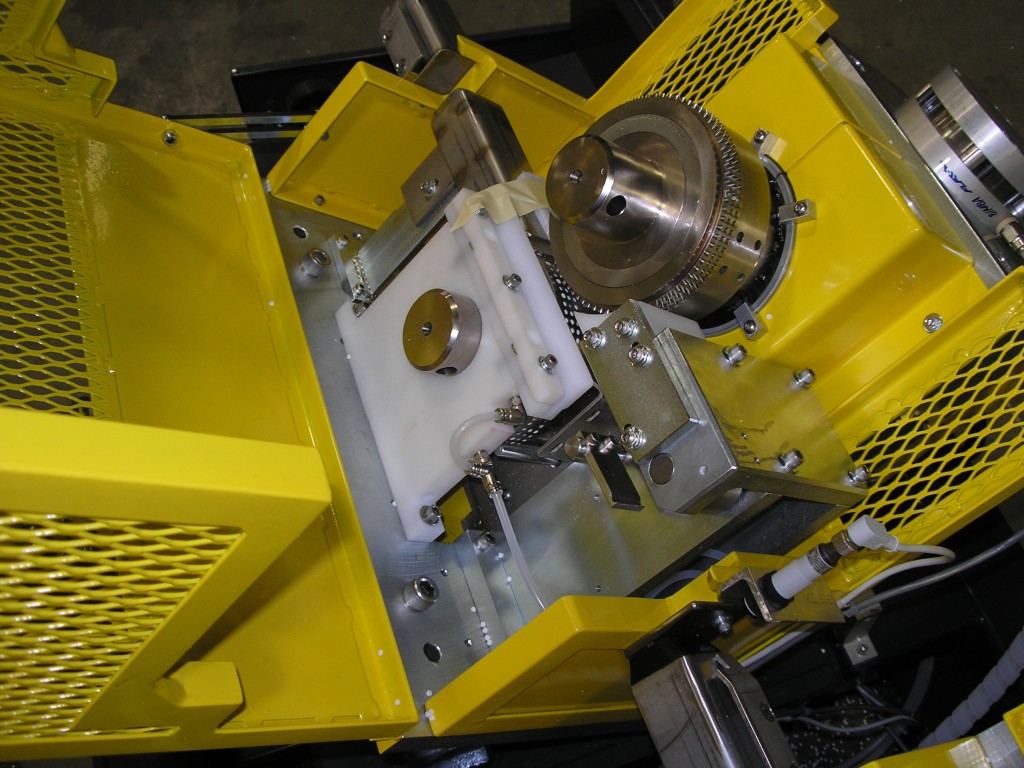

Basket weave perforators are also specially designed for high speed perforation of vinyl soffit. They may be used in the production line or off line as desired by the production crew.

All punching wheels and die wheels are machined to exacting tolerances. This precision punching mechanism will eliminate most of the product distortion normally encountered in this application.

Patterned hole and basket weave perforators can be designed to perforate center vinyl, double five, triple four, or other profiles of soffit with ease, along with Corner Bead (for Plastering applications). Replacement components are reasonably priced and precision made.

Drive motors are AC powered & geared to operate at the customer’s optimum operating speeds. Customer specification of electric drive manufacturer is encouraged to standardize electrical equipment on the production floor. Utilization of a combo PLC\HMI for Speed control & machine functions make operation easy!

Adjustable product guides and fully enclosed safety guards are standard on all rotary perforators.

We can also rebuild existing patterned hole or basket weave perforators and manufacture any needed replacement parts for the worn equipment.

In order to perforate extruded vinyl, an extremely rugged and accurate machine is needed. Alignment of punches to dies is critical to long cutting life and a quality product.

Our perforating machines accomplish this through use of zero backlash gearing. This gearing, along with holding tight tolerances on all parts, produces a machine that will enhance productivity and improve quality.

We also manufacture machines to produce a basket-weave pattern. The absence of slugs makes this a desirable process to some manufacturers.

Remember custom is what we do!

Please contact us with your specific requirements. Our expert staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Design & Build, Videos, Vinyl Tooling