Scrap Cutter

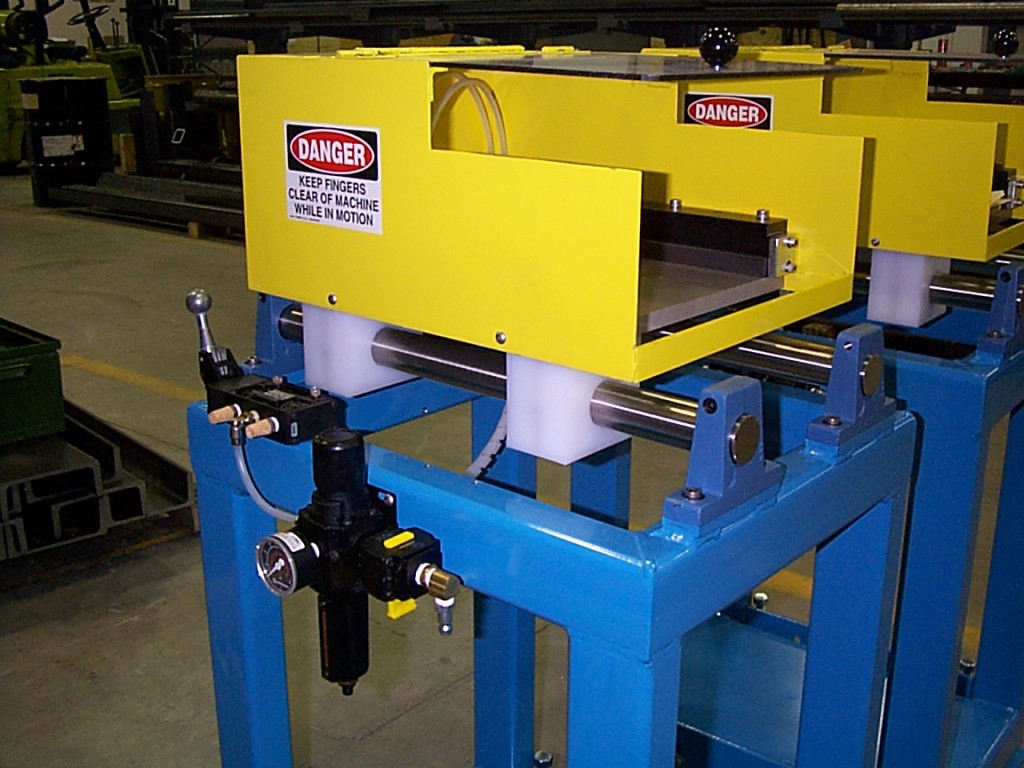

Our scrap cutting machines are designed to contribute to the safety of your operation. Scrap is cut into manageable lengths for regrinding or removal. They eliminate the need for cutting the product with saws or shears and the injuries associated with these methods. Our optional accumulator keeps scrap off of the floor, preventing tripping and slipping hazards. They also reduce the man-hours required during product set-up.

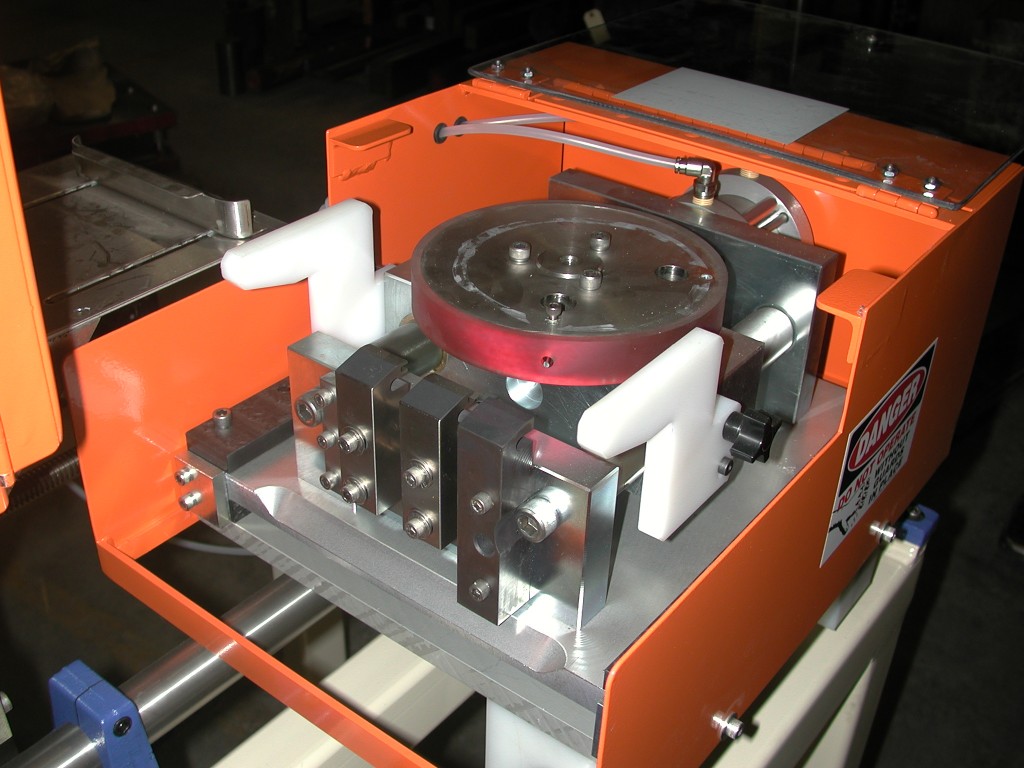

The design of our machine incorporates two knives mounted in rotating shafts. Zero backlash gearing connects the shafts. This causes the material to be cut in a shearing action. The knives are manufactured from Hardened Tool Steel and can be sharpened.

The machine has adjustment to work at most product flight line heights. A speed potentiometer varies the speed of the 5 horsepower DC motor to match the product speed. Speeds up to 240 feet per minute can be accommodated. An adjustable timer is used to vary the length of the scrap to suit the customer’s needs.

We are able to supply a variety of options for this machine. The frame can be supplied with casters to allow either in-line or cross-line movement of the machine. Another frame option is a swing-frame arrangement, which swings the entire machine out of the product line. An optional accumulator table is available to capture the scrap until it can be transferred to a rack or cart. The table has a pneumatic dump action to make this a fast and convenient operation.

The machine is fully guarded and interlocked to guarantee safe operation.

Remember custom is what we do!

Please contact us with your specific requirements. Our engineering staff awaits the opportunity to meet your needs!!

- Published in Custom Machine Building, Design & Build, Vinyl Tooling

Rotary Weep-Hole

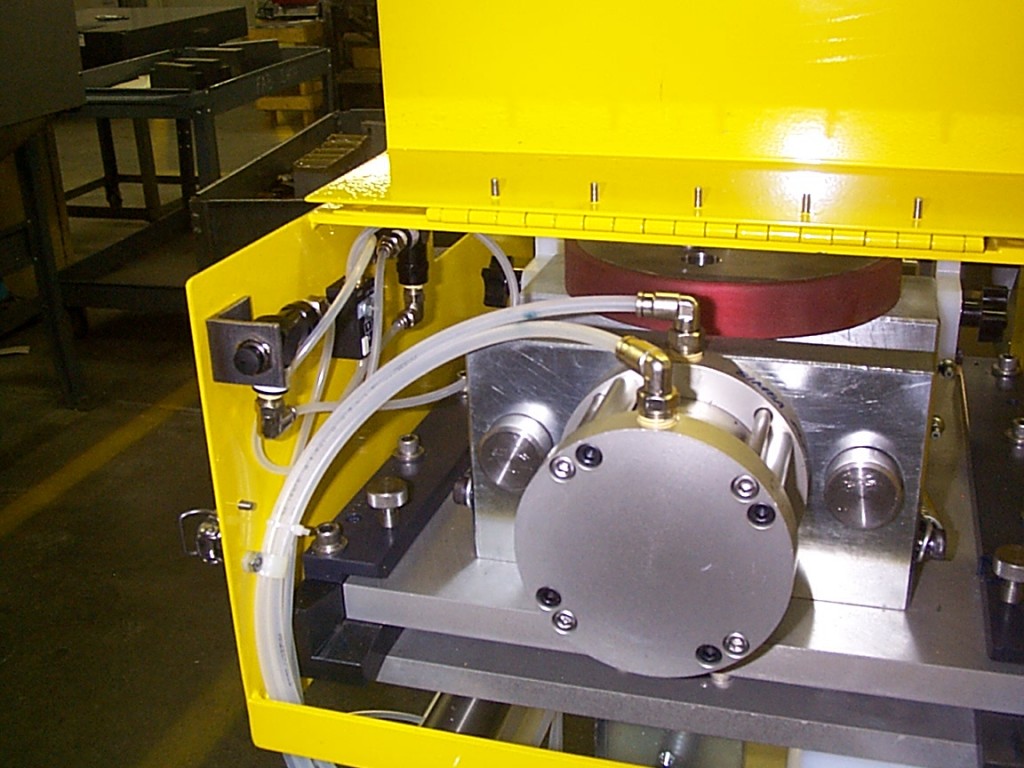

Similar to our Nailslotting line, our Rotary Weep-hole Punch Inserts or Drag style Weep-Hole Punches are being used by a large number of vinyl siding manufacturers at line speeds in excess of 200 feet per minute. They have proven to be effective in producing a quality product while helping to reduce manufacturing costs. Their durability and quality results have made them the choice of many extruded vinyl manufacturers.

The punch wheel is Urethane coated and driven by the product. The punches and anvils are manufactured from high-speed steel and machined to match the customer’s product profile, producing a clean cut. A pneumatic cylinder is used to engage and disengage the punch wheel from the product.

The Weep-hole units are supplied as a quick-change insert. The Weep-Hole Insert can be mounted by itself or on a Puller Mount Quick Change Plate, Stand Alone, or with another piece of equipment, such as a Nailslotter, or Puller. Using our Standard Quick Change Mounts, customers can change a Weep-Hole Insert in less than one minute!

Our Weep-Hole Inserts have many features that bring a quick payback to the user. They have been designed to be both durable and light. The ease of adjustment and sharpening helps reduce the cost of maintenance. The use of durable Hardened Tool Steel & Carbide for cutting edges extends tool life. Other Weep-Hole components are made from anodized aluminum, Bronze, Zinc Plated mild steel or stainless steel to minimize corrosion.

Remember custom is what we do!

Please contact us with your specific requirements. Our expert staff awaits the opportunity to meet your needs.

- Published in Custom Machine Building, Vinyl Tooling